When it comes to choosing the right air impact wrench for your job, the caliber and torque are two of the most important factors to consider. The caliber, or drive size, determines the size of the sockets the wrench can accommodate, while the torque determines the power and force the wrench can deliver. Here’s a guide to help you make the best choice:

1. 1/4-inch air wrench

Suitable for: DIY enthusiasts,light-duty work, fasteners in electronics, and small machines repair.

Torque Range: Typically 3-40 ft-lbs.

Applications: Ideal for light-duty tasks such as electronics repair, small engine maintenance, and minor automotive work. For example, a 1/4-inch drive wrench can be used to tighten or loosen small bolts in a motorcycle engine.

2. 3/8-inch air wrench

Suitable for: General automotive work and medium-duty tasks.

Torque Range: Usually 7-75 ft-lbs.

Applications: Suitable for medium-sized fasteners and general repairs. A 3/8-inch wrench is perfect for tasks like changing oil filters or performing routine car maintenance.

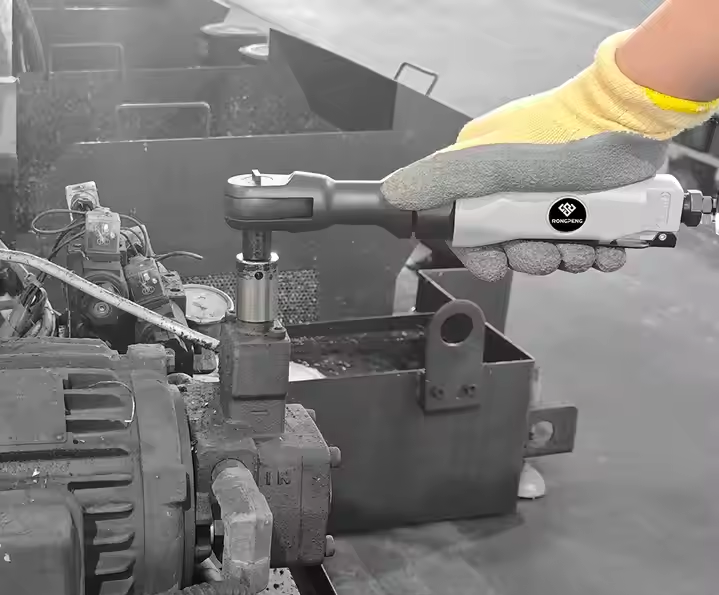

3. 1/2-inch air wrench

Suitable for: Professional mechanics, automotive technicians, and industrial workers.

Torque Range: Generally 400-1200 ft-lbs.

Applications: This is the most common size for automotive and light industrial use. It can handle larger fasteners and is suitable for tasks such as tire changes, engine repairs, and bodywork. For instance, a 1/2-inch drive wrench with 500 ft-lbs of torque can easily remove lug nuts during a tire change.

4. 3/4-inch and 1-inch air wrench

Suitable for: Heavy-duty industrial applications and professionals working on large machinery.

Torque Range: 800-2000 ft-lbs and above.

Applications: These larger drives are designed for very large fasteners and heavy equipment. A 3/4-inch drive wrench is often used in truck maintenance and commercial machinery servicing, while a 1-inch drive wrench is ideal for tasks like maintaining large engines and industrial equipment. For example, a 1-inch drive wrench with 1800 ft-lbs of torque can handle the large bolts on a semi-truck’s wheel.

Considerations for Specific Users

For beginners, a small 1/4-inch or 3/8-inch pneumatic wrench is a great starting point. These tools are lightweight and easy to maneuver for small projects around the home or garage. Or there are professionals who may also use them in the assembly and repair of small machines and electronic equipment.

Professional mechanics often need a range of wrenches of different calibers and torques to handle a variety of tasks in an auto repair shop or manufacturing facility. 1/2-inch wrenches are the most widely used option for everyday use, but sometimes 3/4 or 1-inch wrenches are used.

Those working in heavy industry or on large machinery need the high torque and large diameter of a 3/4-inch or 1-inch impact wrench. These tools are designed to withstand the rigors of industrial use and provide the specifications needed for heavy-duty applications.

Considering the specific requirements of the job, the type of fastener, and the environment in which it will be used, you can choose the most appropriate caliber and torque air impact wrench to ensure efficient and effective results.