Impact wrenches are a must-have for automotive repair shops, industrial settings, and home garages. To get the most out of your impact wrench while proper use and technique are essential.

Choosing the Right Impact Wrench

Consider these factors when selecting an impact wrench.

Drive size. 1/2”drives are common. Match this to the bolt/nut sizes you’ll be working with.

Torque output. Expressed in ft-lbs, higher is better for heavy duty jobs. But too much torque risks damage. Air wrenches are more powerful but need a compressor.

Choose a weight and grip design that feels comfortable and allows good control.

Setting Up the Air Supply

Pneumatic impact wrenches require a proper air supply to operate optimally.

Use a compressor that provides sufficient CFM at 90 PSI for the wrench's air consumption needs. Undersized compressors can lead to loss of power.

The air hose must be large enough to minimize pressure drop. A 3/8" I.D. hose is sufficient for most impact wrenches.

Add an oiler to properly lubricate the wrench and prevent premature wear. The oiler needs to be sized appropriately for the CFM flow.

Use a filter-regulator to remove moisture and debris and regulate pressure down to 90 PSI from the compressor.

Position the compressor as close as possible to the point of use to maximize delivered air pressure.

Proper air supply setup prevents pressure drops that can reduce torque. Consult the RONGPENG wrench manual for specific requirements.

Proper Handling of Stuck Bolts

Even the mighty impact wrench sometimes meets its match. For stubborn, stuck, or rusty bolts:

Apply penetrating oil - Soak bolts for several minutes before attempting to loosen.

Start with low speed/torque - Try to break the bolt loose before using full power.

Bear down hard - Apply your weight behind the wrench to maximize impact force.

Use an extension - For better leverage and angle of attack on the bolt head.

Heat it up - Warming stuck metal parts with a torch can help break things loose.

Drill/grind if necessary - Removing a damaged or rounded-off head may be required.

Know when to quit - Attempting to force a badly stuck bolt can result in broken tools or hardware.

Proper Handling and Operation

Operating an impact wrench takes some technique and finesse.

Maintain a firm two-handed grip at all times, placing your dominant hand on the rear handle. This gives maximum control and helps counteract the torque reaction.

Position your body stable and balanced. Place your feet shoulder width apart with knees bent slightly.

When starting to loosen a stubborn bolt, gradually pull the trigger to build torque. Don't just jam it on full power right away.

Keep the impact wrench perpendicular to whatever you're working on as much as possible. This prevents snapping off bolts and sockets.

Let the tool do the work. Don't force it when driving/removing fasteners.

Use light touch-up trigger pulls to precisely position fasteners, then full power to tighten down or break them free.

Equip your shop with RONGPENG R916 air impact wrench suited to your needs and use these tips to incorporate it safely into your workflows.

With 810 ft-lbs of max torque, this rugged impact wrench powers through the toughest bolts and hardware with ease. The swing knob is used to reverse the direction, and the forward rotation is equipped with 3 gears. Handle exhaust design to reduce noise.

Optimized the appearance of the design, the appearance is treated with aluminum alloy spray treatment, the design tool's center of gravity makes the tool have no forward feeling, and the hand feel is the best in the same specification.

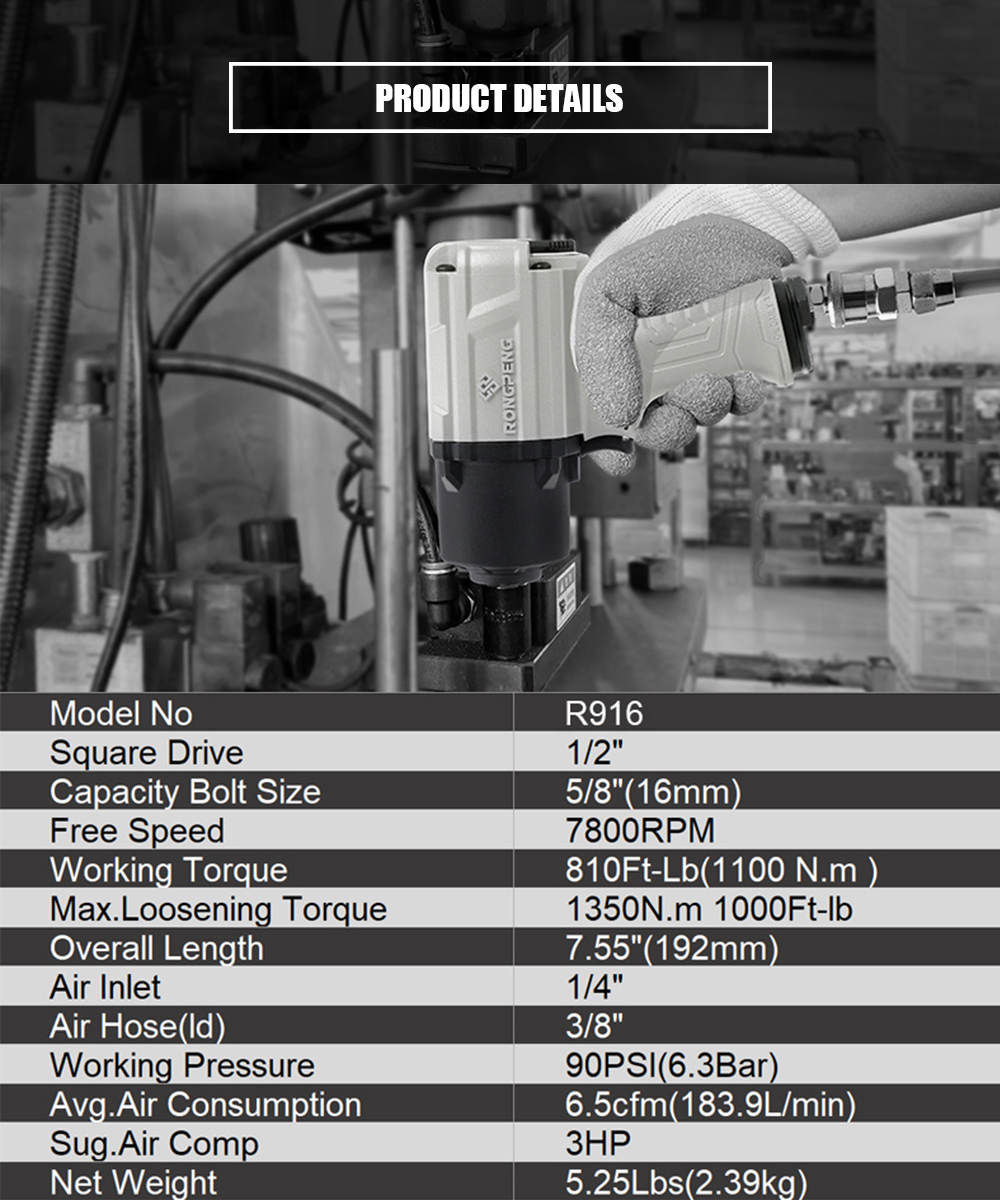

Model: R916

Square Drive: 1/2''

Capacity Bolt Size:5/8”(16mm)

Free Speed: 7800RPM

Working Torque: 810ft-lb(1100N.m)

Air Inlet (NTP): 1/4''

Air Hose(ID): 3/8''

Net Weight: 2.39kg

Avg.air Consumption: 6.5cfm

Sug.air Comp: 3HP

Overall Length: 192mm

Working Pressure: 90PSI

RONGPENG has quickly risen to become an unrivaled global producer of air-powered devices including air tools, air spray gun, air nailer, airless paint sprayer, and etc.

RONGPENG seeks independent sales agent to represent and market our industry-leading pneumatic tools. We support OEM, ODM, OBM customization, small order quantity is acceptable and samples are available.

Make any cooperation possible. Any services related to the product, inquire with us now! Rongpeng@Rongpeng.Com