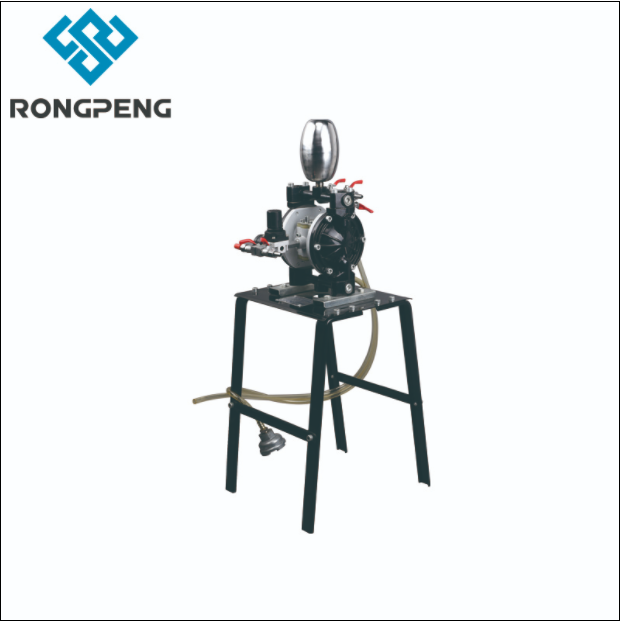

Pneumatic diaphragm pump-the best helper for spray gun

Pneumatic diaphragm pumps and pressure barrels are very common for spray paint equipment in the spray industry. Among them, it is widely used in the petroleum, chemical, electronic, and spraying industries. No matter it is crude oil, resin, paint or mortar, mud, lubricating oil, etc., there is no pressure for pneumatic diaphragm pumps. So what are the advantages of pneumatic diaphragm pumps for other spraying equipment?

First of all, we need to know the pneumatic diaphragm pump: mainly suitable for automatic spray guns or spraying operations that require stable flow. Pressure barrel: mainly suitable for manual spray guns or spraying operations where the spraying requirements are not very high (glue spraying).

First, their stability is different; the stability of the two is obviously different, the pneumatic diaphragm pump has the function of stabilizing the flow, and the pressure barrel will be more or less unstable under the control of the air pressure.

Second, the material is different

Pneumatic diaphragm pumps are mainly composed of three types of materials: aluminum alloy, stainless steel, and engineering plastics.

Aluminum alloy: It has mild corrosion resistance and cannot be used in halogenated liquids. Suitable for glue, water-based paint, oil organic solvent, ceramic glaze water, etc.

Stainless steel: 304/316 stainless steel has strong corrosion resistance and wear resistance.