Replacing a wheel hub is a common repair job for DIY mechanics or professional auto technicians. An impact wrench makes the task much easier by providing ample torque to remove the lug nuts and hub assembly bolts.

We'll walk through the most common impact wrench mistakes people make during a hub replacement job, as well as some tips for avoiding them.

The Wrong Direction

Impact wrenches provide incredible torque, but that torque will be working against you if the wrench is spinning in the wrong direction. Most impact wrench manufacturers stamp an arrow indicating the direction of rotation right on the housing. Before you start impacting lug nuts or caliper bolts, double check you have the direction set properly. Spinning bolts the wrong way will not loosen them – it will just damage the threads and leave you in worse shape than when you started.

Choosing the Wrong Socket

Impact wrench sockets are thicker and made of durable steel that won't crack under torque. Using a standard socket can lead to cracking or slipping which damages the bolt heads. Double check you have the precise metric or SAE impact socket needed for the lug nuts and hub bolts on your vehicle. The socket must fit snugly or it could dislodge under pressure.

Forgetting to Loosen Lug Nuts

It's easy to forget to crack loose the lug nuts while the wheel is still on the ground. This forces you to bear down with full pressure on the wrench once the wheel is in the air. Not only does this make the job much harder, but it also risks spinning the whole car off the jack stand. Always loosen lugs before jacking up the assembly.

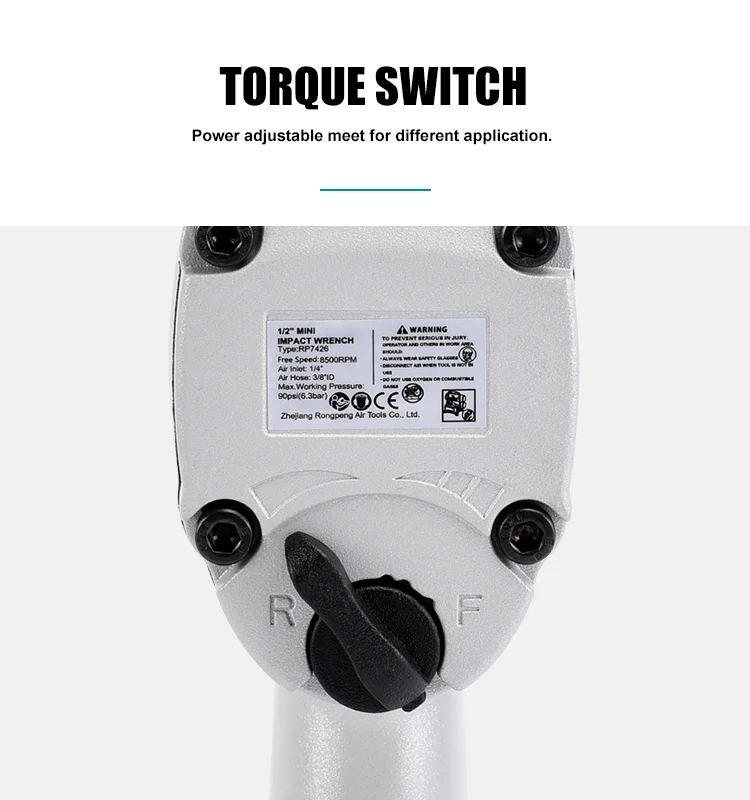

Neglecting the Speed Setting

Impact wrenches typically offer multiple speed settings. For delicate tasks like hub removal and installation, always start with the lowest setting. Using high speeds can damage the bearing seals, internal components, and even the threads themselves. Gradually increase the speed only if necessary for stubborn bolts, but never exceed the recommended speed for the specific task.

Improper Impact Wrench Use

While impact wrenches make the job easier, they also bring risk if used improperly. The extreme torque can crack bolts or damage new parts if you overdo it. Follow the application guidelines and back off the setting if you encounter resistance. It also helps to hand thread new bolts into place before finishing tightening with the wrench.

Installing Unclean Parts

Failing to thoroughly clean all mating surfaces before installation leads to premature failure. Debris left on the hub, brake rotor or backing plate prevents proper sealing and contact. Take time to wire brush and shop vacuum all components before reinstalling. This prevents contamination that degrades operation.

Forgetting a Critical Fastener

Complex hub assemblies feature multiple bolts, washers and o-rings needing precise torque specs and positioning during reassembly. Failing to note where each fastener came from or neglecting installation of a certain component risks failure down the road. As you disassemble, bag and tag fasteners and components together or lay them out in order. Taking photos along the way helps avoid mistakes too when putting everything back together.

Upgrade toolbox and experience the difference the RONGPENG RP7426 1/2 Inch Mini Impact Wrench can make. Compact design only 112mm length,better for narrow space operation.

Upgrade toolbox and experience the difference the RONGPENG RP7426 1/2 Inch Mini Impact Wrench can make. Compact design only 112mm length,better for narrow space operation.

Weighing only 2.5 lbs, the RP7426 won't wear out your hand or wrist even after long repair sessions. Its short nose profile neatly fits into cramped tight spots between components too.

Aluminum die-casting gun body, good air tightness. Impact part, drive shaft, rotor are processed by Ipsen heat treatment equipment which we imported from Germany, ensuring a more durable wear, greatly extend the lifetime. It tackles heavy duty assembly and disassembly applications, suspension work, and industrial equipment repair.

Model Number:RP7426

Free Speed:8500 RPM

Bolt Capacity:16mm

Square Drive:1/2"

Air Hose:3/8" ID

Max Torque:450ft/lbs(610N.m)

Avg Air Consumption:5cfm(142.5L/min)

Sug. Air Comp:3HP

Air Inlet:1/4" NPT

Net Weight:2.64Lbs(1.2kg)

RONGPENG has quickly risen to become an unrivaled global producer of air-powered devices including air tools, air spray gun, air nailer, airless paint sprayer, and etc.

RONGPENG seeks independent sales agent to represent and market our industry-leading pneumatic tools. We support OEM, ODM, OBM customization, small order quantity is acceptable and samples are available.

Make any cooperation possible. Any services related to the product, inquire with us now! Rongpeng@Rongpeng.Com