In this guide, we'll cover the two main types of guns, the HVLP (air pressure of about 10 PSI at the air cap, air usage of 10 to 25 CFM), the LVLP (air pressure of 10 to 30 PSI, air usage of 5 to 18 CFM), so let's explore their unique features! which will be helpful to you in your work!

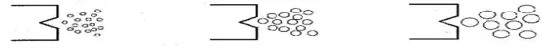

Atomized Particles

HVLP guns use high airflow, low pressure technology to atomize paint into slightly larger particles than LVLP guns

The LVLP gun uses a lower air flow but achieves atomization through a relatively high air pressure to produce fine paint particles.

Transfer Efficiency

Atomization of the HVLP gun is achieved by air volume rather than air pressure, which reduces forward speed and produces a softer spray. The softer spray causes more paint to stick to the workpiece, reducing bounce, air pollution and paint waste, but a small amount of paint will still be dispersed under high airflow operation.

The LVLP gun has the same large air passages as the HVLP gun, but with smaller atomizing holes in the air cap. The smaller atomizing holes create more air pressure at the air cap, which optimizes atomization. Because of the smaller airflow, the paint adheres more easily and therefore escapes less.

Paint application

HVLP sprayers specialize in spraying thicker materials such as metallic paints, primers and undercoats. Their higher airflow allows for better atomization of these materials, resulting in a smoother, more professional finish. Because spraying is done by atomizing the air with the help of high air volume and low air pressure, there is a limit to the viscosity. Generally, viscosities above 18S (Paint-4-Cup Viscometer, 25°C) do not allow for good atomization.

LVLP sprayers are better suited for thinner materials such as stains, varnishes and lacquers. Its lower airflow provides a more controlled application. At the same time the smaller atomizing holes create more air pressure at the air cap to spray coatings with viscosities up to 25S (Coat-4 Cup Viscometer, 25°C).

Spray Time

HVLP Guns: Due to the higher air flow of the HVLP gun and the slightly lower spray pressure, the spraying speed is relatively slow and the spraying time is a little longer. However, this does not mean that its efficiency is low, on the contrary, for some operations that require fine spraying, this slower spraying speed is more advantageous to ensure the uniformity and quality of the coating.

LVLP Guns: LVLP guns have lower air flow, slightly higher spray pressure, faster spray speeds and shorter spray times for jobs that need to be done quickly, or for large workpieces and high-volume applications.

Both types of guns have their own advantages in practical application, and you need to select the best HVLP or LVLP air spray gun that is more suitable for the workpiece you want to spray and the paint you need to apply.

We have lots of auto repair products, welcome to contact us

https://www.rongpeng.com

For more information you can contact with Whatsapp:+86 13906596225