Rongpeng

Release time: 2021-10-16 11:24:58

Rongpeng

Release time: 2021-10-16 11:24:58

How to maintenance of the spray gun?

It is best to lubricate the spray gun after working every day and lubricate the parts with a light machine. Due to normal wear and aging, seals, springs, needle valves and nozzles must be replaced regularly. The replacement should be carried out in accordance with the manufacturer's instructions. Because excessive oil will flow into the paint and oil passages, causing spraying defects, you must be very careful when lubricating. The mixing of oil and paint will reduce the quality of spraying. Is this right, welcome to discuss!

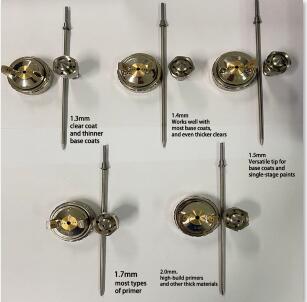

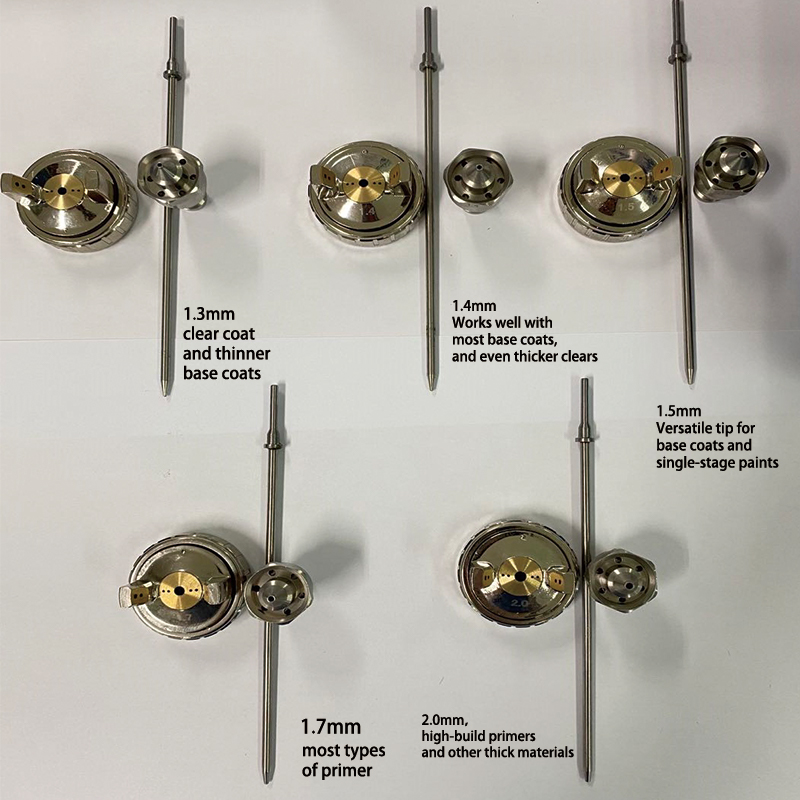

How to select the right tip for my spray paint?

When spraying paint with a compressed air spray gun – whether gravity feed or siphon feed, conventional or High Volume Low Pressure (HVLP) – it’s important to have the gun set up properly for the job. What you are painting is important to a certain extent, but more important is what you are painting with.

However, because it uses high pressures when spraying, a lot of your paint can become overspray. To keep overspray to the least amount possible when using an airless paint sprayer, you should keep the pressures at which your spraying to the lowest PSI possible.

Rongpeng R450 3300 PSI High Efficiency Airless Paint Sprayer The 3300 psi high efficiency airless paint sprayer makes it easier to paint like a pro. The new tip technology decreases overspray by up to 55% while delivering softer spray, improving control and providing a more consistent finish. The 5/8 horsepower pump is a durable powerful Rongpeng sprayer R450 that can spray unthinned coatings with a rebuildable fluid section that maximizes sprayer life.

Ideal for Profession Use Suitable for vehicle, building,shipping, Chemical painting,roofing painting and so on, more infomating please contact with rongpeng@rongpeng.com